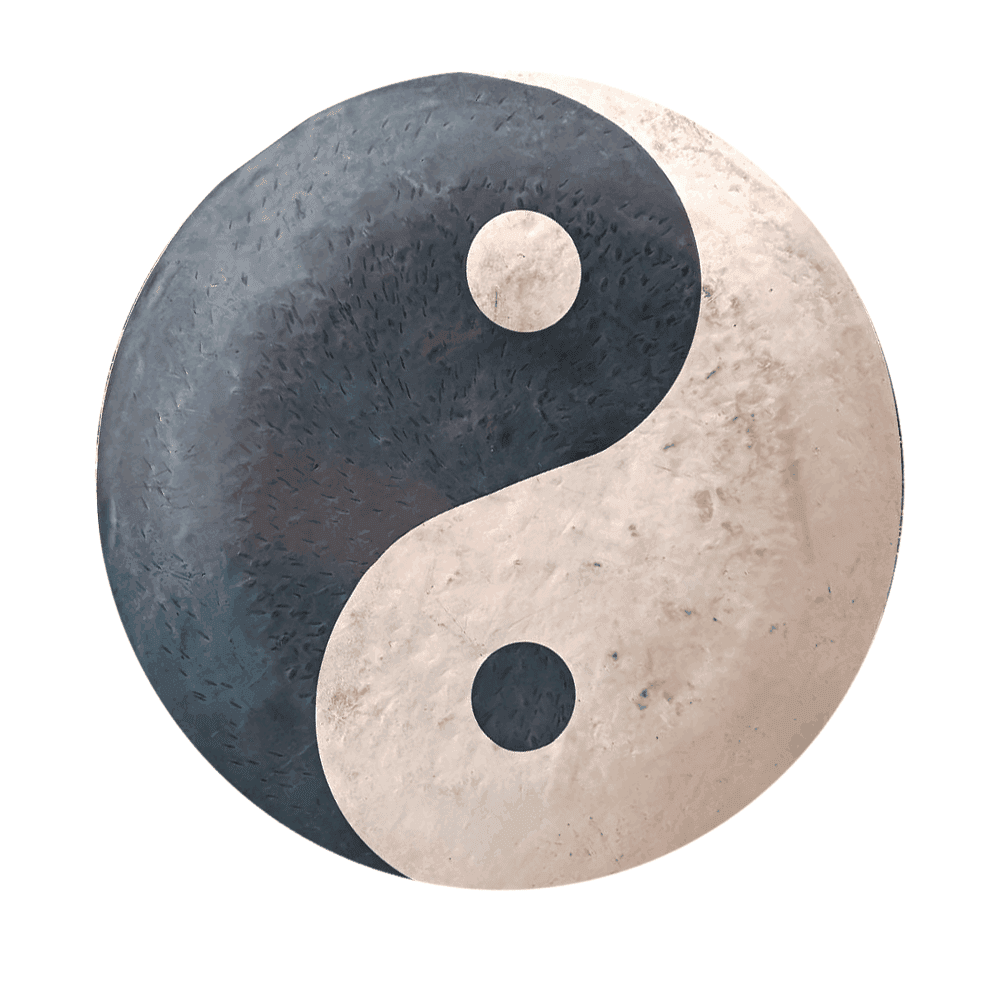

Discover the profound power of authentic Thai craftsmanship with the Mosico Thai Gong. Each instrument represents centuries of traditional metallurgy combined with our commitment to exceptional quality and sound precision.

Handcrafted using time-honored techniques passed down through generations of Thai artisans, our Thai Gongs deliver rich, complex tones that resonate deep within the soul. From the first gentle strike to the lingering sustain, experience sound that transcends the ordinary.

Deep, Resonant Bass Frequencies – Our Thai Gongs produce profound low-end vibrations that create an immersive sonic experience, perfect for meditation, sound therapy, and ambient music creation.

Complex Overtone Series – Each gong generates a sophisticated blend of harmonics and overtones that evolve and develop over extended sustain periods, creating rich textural soundscapes.

Extended Sustain – Premium bronze alloy construction ensures exceptional resonance duration, allowing sounds to bloom and decay naturally over 30+ seconds.

Sound Therapy & Healing

Musical Performance

Wellness & Lifestyle

| Specification | Details |

|---|---|

| Material | Traditional Thai Bronze Alloy |

| Construction | Hand-hammered, artisan-crafted |

| Finish | Natural patina with protective coating |

| Sustain | 30+ seconds |

| Frequency Range | Deep bass fundamentals with rich overtones |

| Included Accessories | Premium felt mallet, care instructions |

Your Mosico Thai Gong requires minimal maintenance to preserve its exceptional sound quality:

At Mosico Cymbal, we bridge ancient traditions with modern quality standards. Our Thai Gongs undergo rigorous quality testing to ensure consistent sound characteristics while honoring the authentic craftsmanship methods that make each instrument truly unique.

Experience the transformative power of authentic Thai Gong artistry. Order your Mosico Thai Gong today and begin your journey into deeper sound and inner peace.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email