| Material: | B20 |

|---|---|

| Color: | Normal |

| Pack: | carton |

| Diameter | 10'' bell, 10'' china, 10'' rocket gong, 10'' splash, 11'' splash, 12'' china, 12'' rocket gong, 12'' splash, 13'' hihats, 14'' air o-zone effect, 14'' china, 14'' crash, 14'' hihats, 14'' oz12 effect china, 14'' rocket gong, 14''HH+16''C+18''C+20''R+CYMBAL BAG, 14"h+16"c+20"R + cymbal bag, 15'' crash, 15'' hihats, 16'' air o-zone effect, 16'' china, 16'' crash, 16'' medium crash, 16'' oz12 effect china, 16'' rocket gong, 17'' air o-zone effect, 18'' air o-zone effect, 18'' china, 18'' crash, 18'' medium crash, 18'' oz12 effect china, 19'' crash, 19'' medium crash, 19'' ride, 20'' china, 20'' crash, 20'' heavy ride, 20'' medium ride, 20'' oz12 effect china, 20'' ride, 21'' heavy ride, 21'' medium ride, 21'' ride, 22'' heavy ride, 22'' medium ride, 22'' ride, 23'' heavy ride, 23'' medium ride, 24'' ride, 6'' bell, 6'' splash, 7'' splash, 8'' bell, 8'' china, 8'' rocket gong, 8'' splash, 9'' splash |

$11.00 – $284.00Price range: $11.00 through $284.00

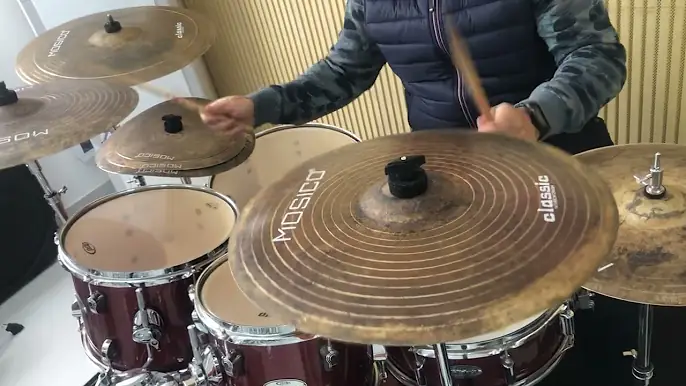

Professional Mosico Extreme Cymbal Set – Maximum Power & Uncompromising Performance

The ultimate power cymbal package engineered for the most demanding extreme musical applications and high-volume performance environments. This comprehensive Extreme collection delivers uncompromising power, exceptional durability, and maximum projection while maintaining the musical character essential for professional extreme music performance.

Complete Power Collection Includes:

Set Features:

Technical Specifications:

Extreme Performance Features:

Ultimate Value Proposition:

Perfect For:

Ultimate Power Package Includes:

Extreme Performance Support Services:

Durability Assurance:

Professional Extreme Applications:

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email