| Material: | B20 |

|---|---|

| Color: | Normal |

| Pack: | carton |

| Diameter | 14 inch, 15 inch, 16 inch, 18 inch, 19 inch, 20 inch |

$37.00 – $87.00Price range: $37.00 through $87.00

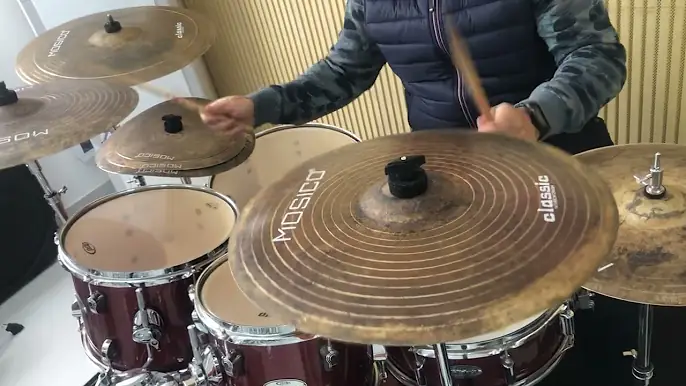

Professional Mosico Delta Crash Cymbal – Brilliant Attack & Musical Sustain

The Mosico Delta Crash Cymbal represents the pinnacle of modern cymbal craftsmanship, delivering explosive attack with rich, musical sustain. Featuring Mosico’s proprietary Delta hammering technique and brilliant finish, this crash cymbal produces crystalline highs, warm mids, and controlled low-end response. The innovative alloy composition ensures consistent performance across all dynamic levels while maintaining exceptional durability.

Key Features:

Technical Specifications:

Advanced Features:

Ideal for: Rock, pop, fusion, progressive, studio recording, live performance, contemporary worship, world music

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email