| Material: | Alloy |

|---|---|

| Color: | Colorful |

| Pack: | carton |

| Diameter | 10 inch, 12 inch, 13 inch, 14''HH+16''C+18''C+20''R+CYMBAL BAG, 16 inch, 18 inch, 8 inch |

| Types | A set, CHINA, HIHAT, SPLASH |

$29.00 – $62.00Price range: $29.00 through $62.00

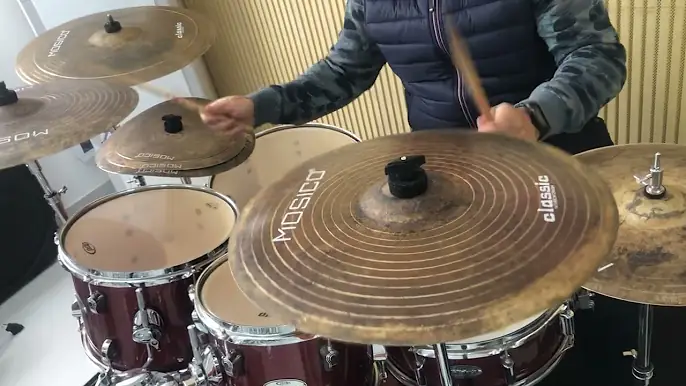

Professional Mosico Green Mute Cymbal Set – Complete Eco-Friendly Music Solution

The ultimate sustainable cymbal package combining environmental responsibility with professional performance, featuring innovative green technology and eco-friendly manufacturing processes. This comprehensive Green Mute collection delivers exceptional musical expression while supporting environmental stewardship through revolutionary sustainable cymbal innovation and carbon-neutral production.

Complete Sustainable Collection Includes:

Set Features:

Technical Specifications:

Eco-Innovation Features:

Sustainable Value Proposition:

Perfect For:

Sustainable Collection Includes:

Environmental Support Services:

Environmental Certifications:

Sustainability Features:

Green Music Applications:

Artist using this set

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email