| Material: | 80%copper+20%Tin |

|---|---|

| Process: | 100% hand made |

| Color: | white edge |

| Pack: | carton |

| Diameter | 10 inch, 12 inch, 14 inch, 16 inch, 18 inch, 20 inch, 22 inch, 24 inch, 26 inch, 28 inch, 30 inch, 32 inch, 34 inch, 36 inch, 38 inch, 40 inch, 48 inch, 52 inch, 6 inch, 8 inch |

$25.00 – $4,370.00Price range: $25.00 through $4,370.00

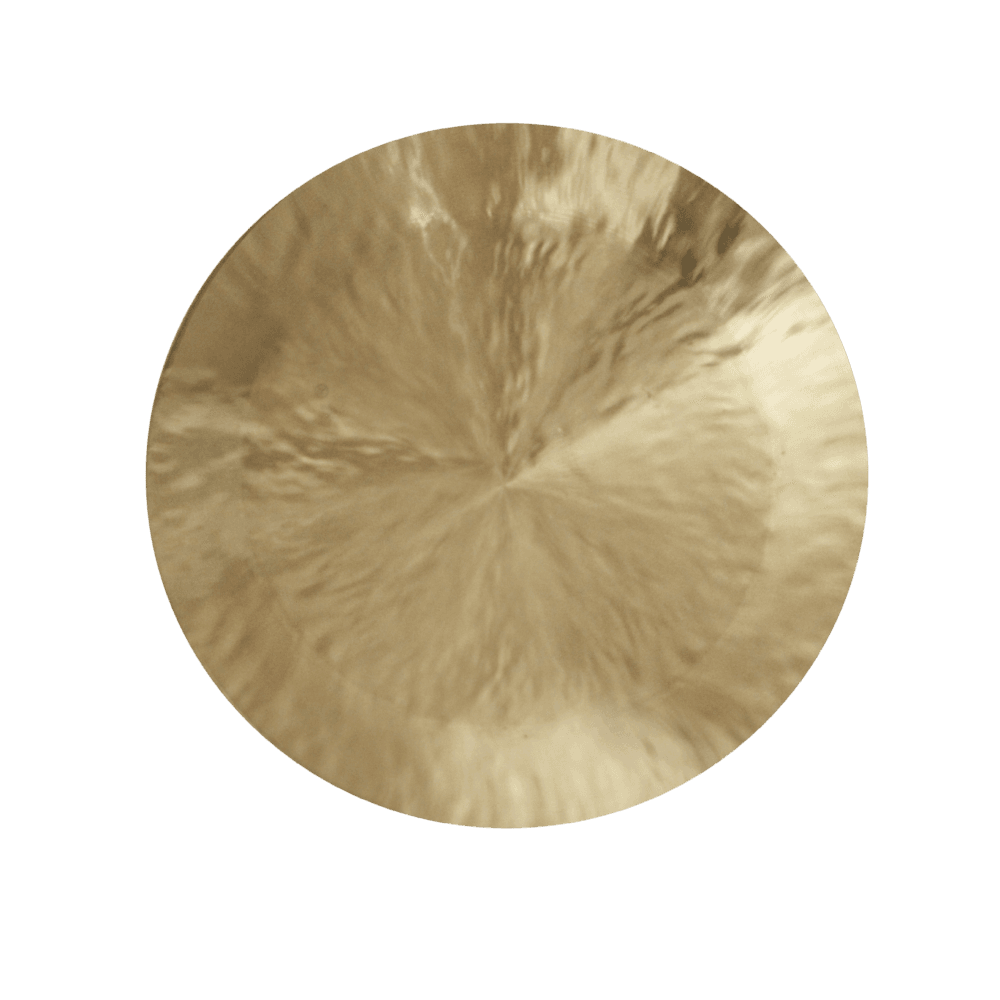

Experience the pure essence of traditional Chinese percussion with the Mosico Tai Loi Chau Gong. This authentic instrument honors centuries of Chinese gong-making tradition while incorporating our modern alloy innovations to deliver the classic “tai loi” (大鑼) sound that has defined ceremonial, theatrical, and musical performances throughout Asia for generations.

Hand-forged using time-honored techniques passed down through master craftsmen, each Tai Loi Chau Gong embodies the powerful, commanding voice that has announced imperial ceremonies, accompanied opera performances, and marked sacred rituals for over a thousand years. The distinctive raised center boss and graduated thickness create the unmistakable tonal character that makes this gong truly irreplaceable.

Classic Tai Loi Voice – Deep, penetrating fundamental with rich harmonic complexity that builds from a focused attack into a full, enveloping wash of sound that commands attention and respect.

Imperial Presence – The authoritative tone that has historically announced important ceremonies and theatrical entrances, carrying the weight of cultural significance in every strike.

Sustained Power – 60-90 second decay allows the full majesty of the traditional sound to develop completely, creating the extended ceremonial presence essential for authentic applications.

Chinese Opera Tradition

Ceremonial Applications

Historical Significance

| Feature | Traditional Standard |

|---|---|

| Alloy Composition | Traditional Chinese bronze (80% copper, 20% tin) |

| Construction Method | Hand-forged with raised center boss |

| Thickness Profile | Graduated from rim (thin) to center (thick) |

| Surface Finish | Traditional patina with polished boss |

| Tonal Character | Deep fundamental with rich overtones |

| Cultural Accuracy | Historically authentic proportions and sound |

Traditional Sound Profile

Performance Dynamics

Traditional Chinese Music

World Music & Fusion

Theatrical & Performance

Educational Value

Cultural Bridge

Respectful Preservation:

Authentic Diameter Options:

Traditional Authenticity:

Our Tai Loi Chau Gongs represent our deepest respect for Chinese musical tradition. We work directly with master craftsmen who learned their skills through traditional apprenticeships, ensuring that every instrument carries the authentic voice that has defined Chinese culture for millennia.

Perfect For:

Cultural Investment:

Honor the tradition, embrace the authentic voice. The Mosico Tai Loi Chau Gong—where ancient wisdom meets contemporary excellence, where tradition lives on.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email