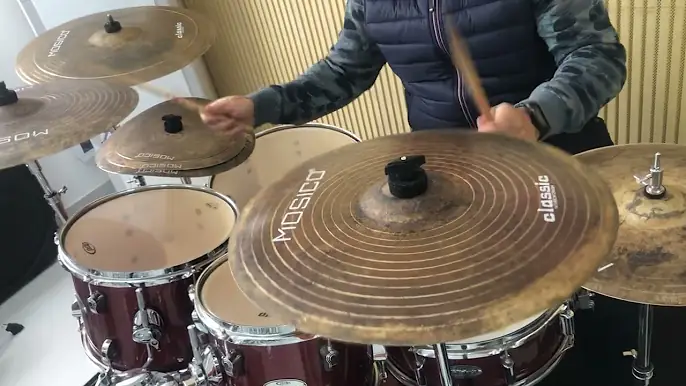

Immerse yourself in the sacred sounds of Thailand with the Mosico Premium Thai Gong. This extraordinary instrument embodies the spiritual heritage and masterful artistry of traditional Thai gong making, delivering unparalleled depth and complexity in every strike.

Meticulously forged by master craftsmen using ancient techniques refined over centuries, each Premium Thai Gong showcases the perfect marriage of traditional wisdom and contemporary precision. The result is an instrument that doesn’t just produce sound—it creates transformative experiences.

Warm, Enveloping Tones – Experience the signature warmth that only authentic Thai bronze can deliver, with fundamental frequencies that seem to wrap around the listener in waves of pure resonance.

Dynamic Harmonic Evolution – Watch as the sound transforms from initial impact through its extended decay, revealing new overtones and subtle frequency interactions that continue to surprise and delight.

Meditative Sustain – Enjoy up to 45 seconds of rich, evolving sustain that naturally guides the mind into states of deep relaxation and contemplative awareness.

Deep Sound Healing

Meditation Enhancement

Energy Work & Ceremony

| Feature | Description |

|---|---|

| Alloy Composition | Traditional Thai Bronze (High Tin Content) |

| Manufacturing | Hand-forged by certified artisans |

| Surface Treatment | Traditional patina with hand-polished highlights |

| Acoustic Properties | Full-spectrum harmonics, extended sustain |

| Resonance Duration | 40-50 seconds typical |

| Mallet Included | Handcrafted felt beater with wooden handle |

Striking Techniques

Positioning & Setup

Preserve your investment with proper care:

Our Premium Thai Gong series represents the pinnacle of traditional gong craftsmanship enhanced by modern quality assurance. Each instrument is individually tested and certified to meet our exacting standards for pitch stability, harmonic richness, and aesthetic beauty.

Backed by our lifetime craftsmanship guarantee and comprehensive sound therapy guide, the Mosico Premium Thai Gong is your gateway to authentic transformational sound experiences.

Transform your practice, elevate your space, and connect with ancient wisdom through the extraordinary voice of the Mosico Premium Thai Gong.

Fanjia Vililage, Shuizhai Town, Zhangqiu City, Shandong, China

Copyright Mosico Cymbal 1996-2025. All Right Reserved.

Supported Payment :

We will contact you within 1 working day, please pay attention to the email